Knit Line

Knit Line - They occur when melt flow fronts collide in a mold cavity. It is created by a core. Web knit lines, weld lines, mold lines, or flow lines in injection molding are faint lines that become visible on certain plastic parts. Just to remind you, a boss is a feature with a hole designed to accommodate a thread fastener. Flow lines are defects that appear as wavy patterns of a slightly different color on the surface of a plastic part. Web what is a knit line? Web weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Knit lines are normal formations, which are often created during plastic injection molding along holes or seams of a mold. Meld and knit lines are actually both different types of. Improve your molded part’s appearance and function by avoiding knit lines. They again get resolidified along the surface. Just to remind you, a boss is a feature with a hole designed to accommodate a thread fastener. Web knit lines in injection molded parts can range from harmless to unsightly to a serious structural problem. A knit line is formed when two or more plastic flows collide and solidify or knit together. Just to remind you, a boss is a feature with a hole designed to accommodate a thread fastener. Meld and knit lines are actually both different types of. Web what causes knit lines in injection molding? Web knit lines in injection molded parts can range from harmless to unsightly to a serious structural problem. Web how to eliminate knit lines. It is created by a core. Learn more about knit lines and how to minimize them with this tip. Web what causes knit lines in injection molding? Present no problem at all,. Web knit lines in injection molded parts can range from harmless to unsightly to a serious structural problem. Depending on the design of the mold and the material being injected, a knit line may: Knit lines are formed in injection molding when two flow fronts meet in the middle of a part (a line where two. Meld and knit lines are actually both different types of. Knit lines are normal formations, which are often created during plastic injection. Web one place where a knit line is an issue is behind a boss. Web weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Meld and knit lines are actually both different types of. Improve your molded part’s appearance and function by avoiding knit lines. Web what are knit lines? Web knit lines, also known as weld lines or meld lines, are visible lines or seams that appear on a molded part where two or more flow fronts meet during the injection. Web weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Web what are flow and knit lines? Weld lines may appear. Web how to eliminate knit lines in injection molding. Meld and knit lines are actually both different types of. Learn more about knit lines and how to minimize them with this tip. In manufacturing, the weld line or knit line or meld line is the line where two flow fronts meet when there is the inability of two or more. In manufacturing, the weld line or knit line or meld line is the line where two flow fronts meet when there is the inability of two or more flow fronts to knit together, or. What are knit lines, and how can you avoid them? Web a knit line is any line, visible or not, where two resin flows meet. Meld. Depending on the design of the mold and the material being injected, a knit line may: Knit lines are formed in injection molding when two flow fronts meet in the middle of a part (a line where two. Flow lines are defects that appear as wavy patterns of a slightly different color on the surface of a plastic part. Web. Web one place where a knit line is an issue is behind a boss. Web weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Web what is a knit line? Three terms that often get mixed up in injection molding are. Weld lines may appear like seams or scratches,. Web what are flow and knit lines? Web what are knit lines? Web what causes knit lines in injection molding? Present no problem at all,. They again get resolidified along the surface. They occur when melt flow fronts collide in a mold cavity. What are knit lines, and how can you avoid them? Web knit lines, weld lines, mold lines, or flow lines in injection molding are faint lines that become visible on certain plastic parts. Web one place where a knit line is an issue is behind a boss. Improve your molded part’s appearance and function by avoiding knit lines. Web a knit line is any line, visible or not, where two resin flows meet. Knit lines are normal formations, which are often created during plastic injection molding along holes or seams of a mold. It is created by a core. Web weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Knit lines are formed in injection molding when two flow fronts meet in the middle of a part (a line where two. Flow lines are defects that appear as wavy patterns of a slightly different color on the surface of a plastic part.

How To Insert a Lifeline Knitting Tutorial YouTube

Learn how to knit within an hour with the complete beginner's guide to

Continental knitting Learn how to knit, Knitting for beginners, Knitting

![How to knit the 1x1 Rib Stitch step by step for beginners [+video]](https://nimble-needles.com/wp-content/uploads/2020/04/rib-stitch-swatch-close-up.jpg)

How to knit the 1x1 Rib Stitch step by step for beginners [+video]

How to Knit the Linen Stitch Free Tutorial on Bluprint Linen stitch

TECHknitting Horizontal fold lines in knitting, part 1 knit sides out

What Are Knit Lines in Injection Molding, and How Do You Prevent Them

How to Knit the Linen Stitch Free Tutorial on Bluprint Breien

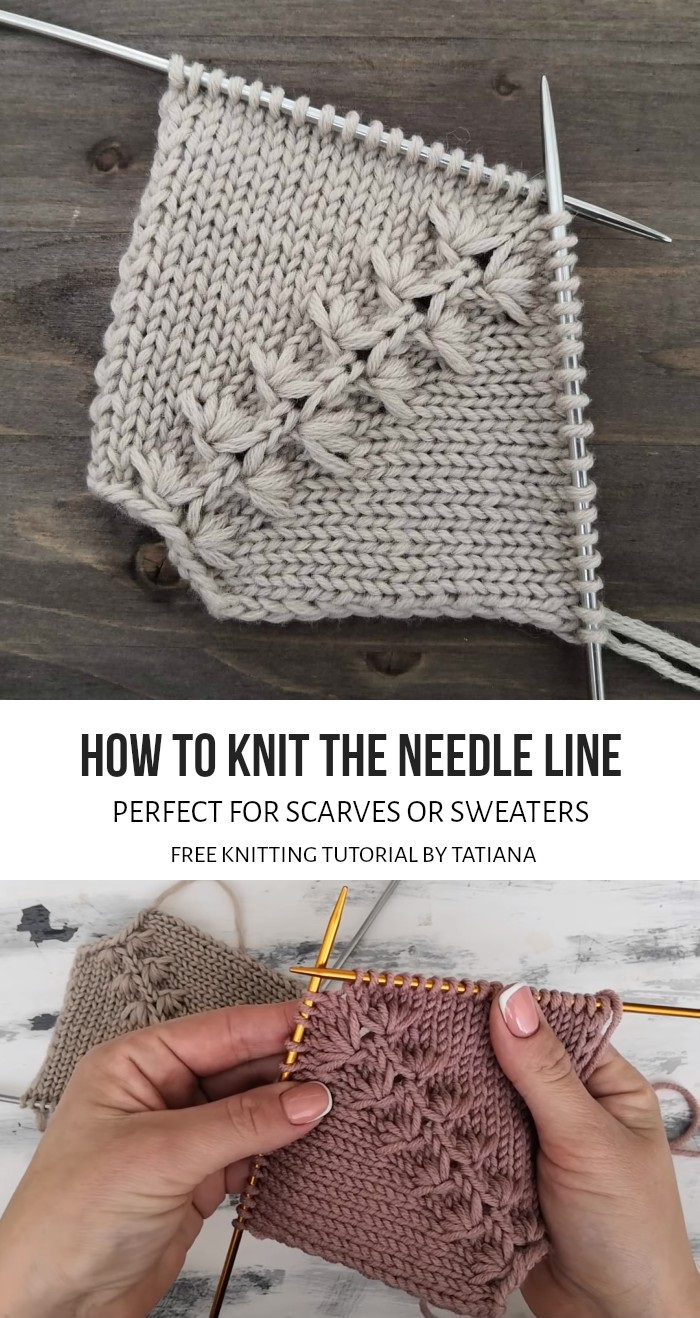

How To Knit The Needle Line

Knit (weld) and meld lines formation principles. Legend aformation of

Web How To Eliminate Knit Lines In Injection Molding.

In Manufacturing, The Weld Line Or Knit Line Or Meld Line Is The Line Where Two Flow Fronts Meet When There Is The Inability Of Two Or More Flow Fronts To Knit Together, Or.

Web Three Terms That Often Get Mixed Up In The Plastic Injection Molding Industry Are Weld, Meld, And Knit Lines.

Three Terms That Often Get Mixed Up In Injection Molding Are.

Related Post: