Knit Lines In Injection Molding

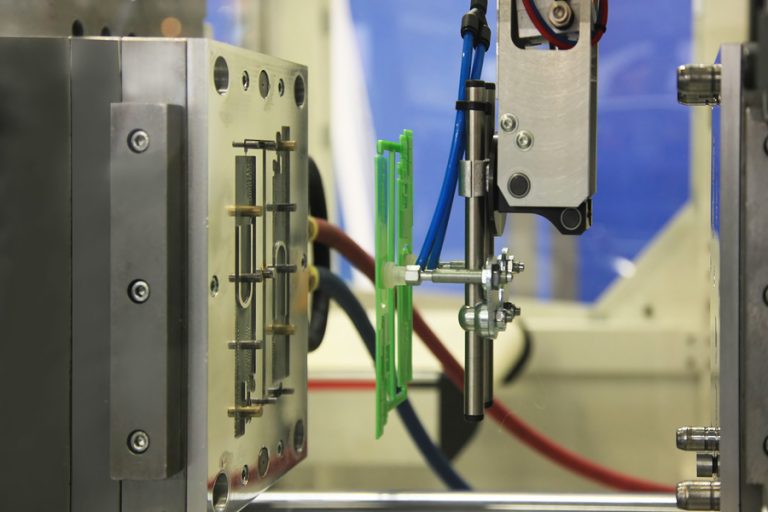

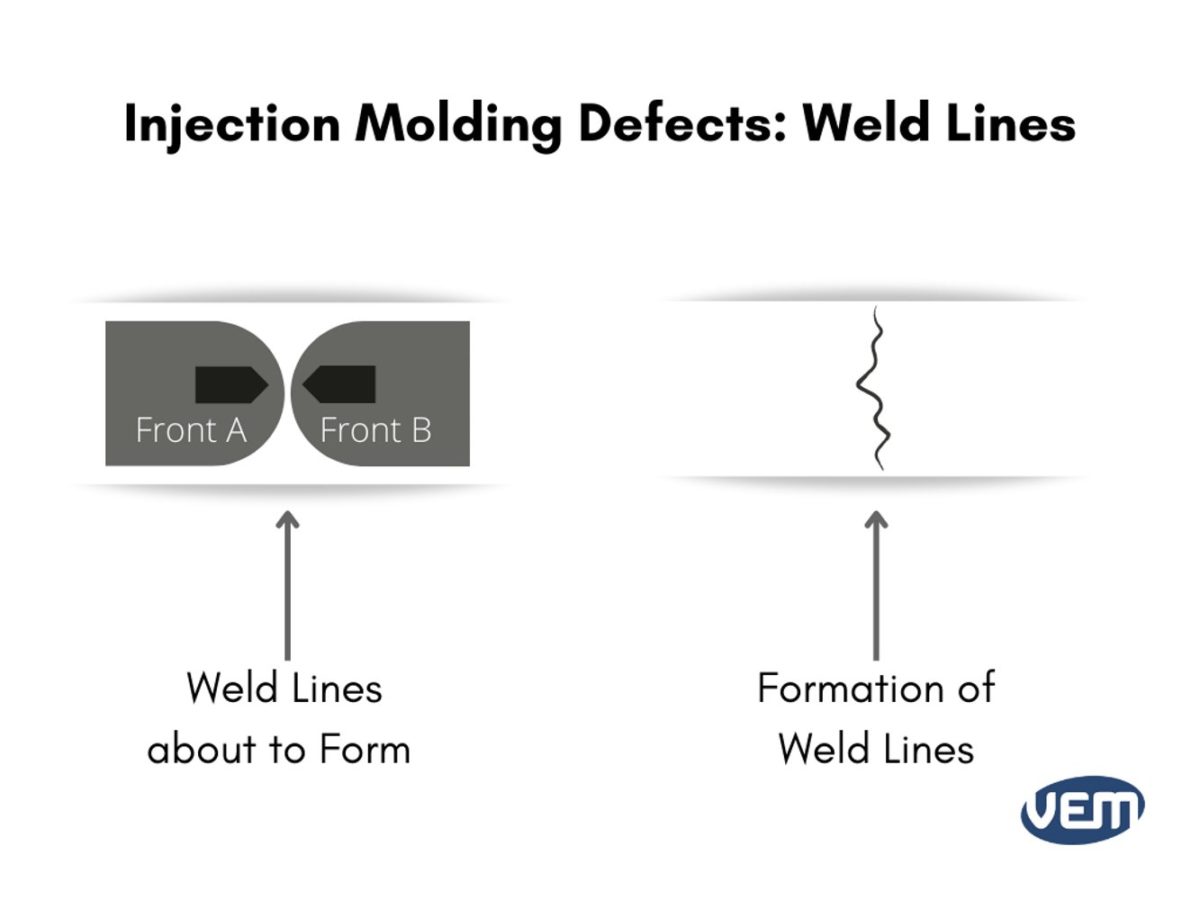

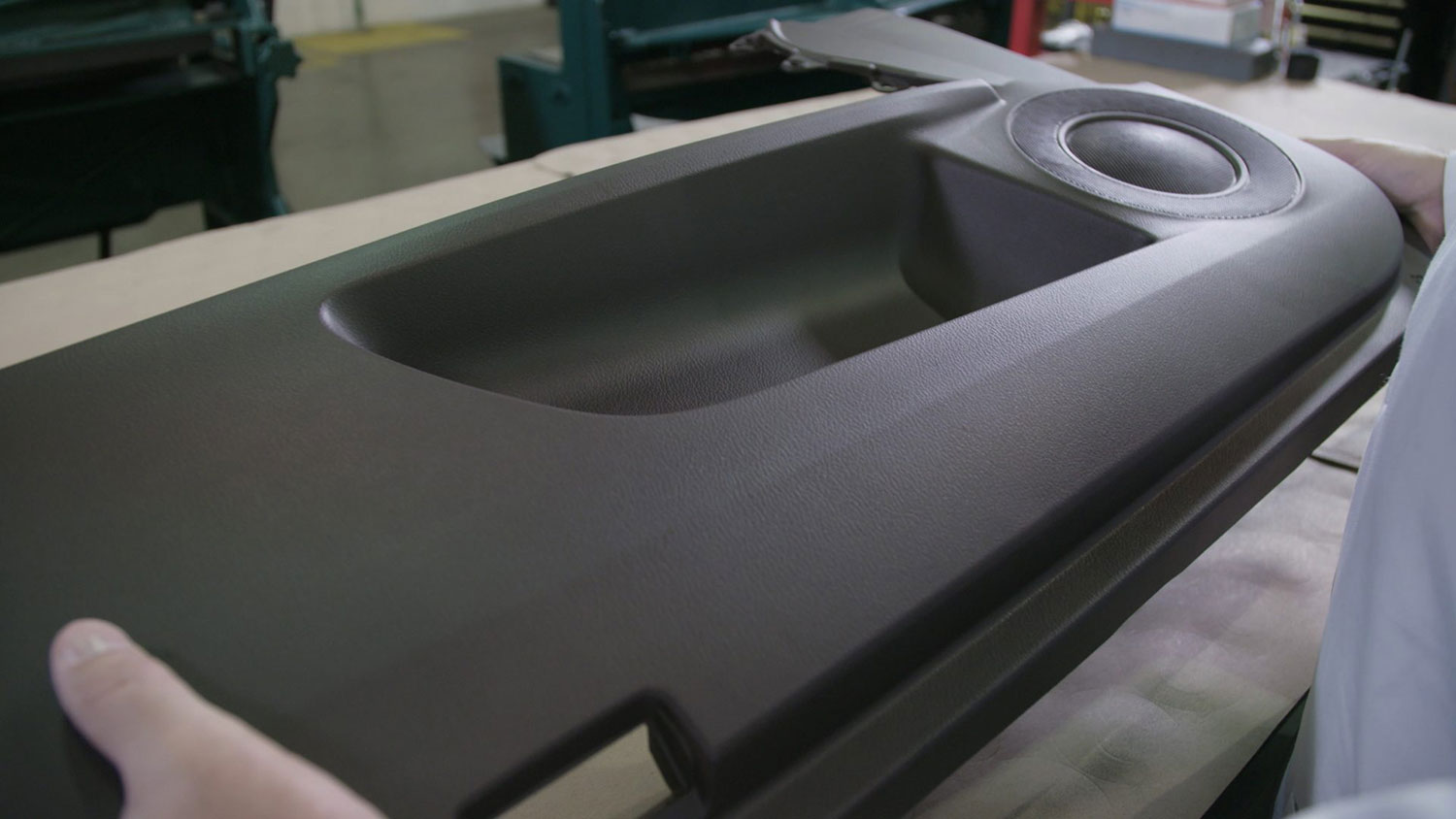

Knit Lines In Injection Molding - When these areas are visible, it can pose no problem at all to the piece, be nothing more than a cosmetic flaw, or can be a source of major structural problems for your piece. A knit line is the spot where two flows meet. What are knit lines, and how can you avoid them? What causes knit and meld lines? The fluidity of the plastic plays an important role in the injection molding process, so seeking the help of an expert manufacturer and mold maker is essential. It happens when the molten plastic material flows around obstacles, such as inserts or cores, and rejoins on the other side. A knit line is any line, visible or not, where two resin flows meet. Knit lines often occur when two flows meet and are held at different temperatures, leaving a line between. A poor knit line can cause only cosmetic blemishes or it can significantly weaken the structural integrity of a part. This most often occurs when you have a core or shutoff feature that the plastic needs to flow around. Here is a look at the differences between them, the causes of meld and knit line imperfections, and their impact on part durability. This defect forms when two or more flow fro Present no problem at all, be a cosmetic issue, or cause a potentially serious structural problem. Weld lines usually come in two types: This most often occurs when. Like many part inconsistencies, these unwanted features are rooted in product design. What causes knit and meld lines? Web what are knit lines? Web weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Let’s review what causes meld and knit line imperfections, how they’re different, and how they affect part durability. Think about how a resin flows through a mold. Web weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Web a knit line is any line, visible or not, where two resin flows meet. These can occur due to various factors such as the design of the mold, material properties, or processing conditions.. Let’s review what causes meld and knit line imperfections, how they’re different, and how they affect part durability. Web what is a knit line? Depending on the resin, resin temperature, mold temperature, and filling speed, knit lines can vary. Web knit lines are formed in injection molding when two flow fronts meet in the middle of a part (a line. Depending on the resin, resin temperature, mold temperature, and filling speed, knit lines can vary. A knit line is the spot where two flows meet. Let’s review what causes meld and knit line imperfections, how they affect part durability, and what the difference between them is. Think about how a resin flows through a mold. This most often occurs when. Web knit lines are considered molding defects, and occur when the mold or/and material temperatures are set too low: A knit line is the spot where two flows meet. Based on the resin temperature, filling speed, and resin, there is a variation in the knit lines. Web a weld line, often referred to as a knit line, represents the junction. Web three terms that often get mixed up in the plastic injection molding industry are weld, meld, and knit lines. Present no problem at all, be a cosmetic issue, or cause a. Like many part inconsistencies, these unwanted features are rooted in product design. Let’s review what causes meld and knit line imperfections, how they affect part durability, and what. Web knit lines appear to be a faint line or a crack in the finished part after it comes out of the injection mold. What causes knit and meld lines? A knit line is the spot where two flows meet. Present no problem at all, be a cosmetic issue, or cause a. Knit lines often occur when two flows meet. Weld lines usually come in two types: Meld and knit lines are actually both different types of weld lines. Weld lines may appear like seams or scratches, but that is not what they are. Web meld and knit lines are actually both different types of weld lines. A poor knit line can cause only cosmetic blemishes or it can significantly. Web knit lines, also known as weld lines, are a common phenomenon in injection molding where two flow fronts of molten plastic converge and solidify without bonding perfectly. Web avoid knit lines when designing a molded part to improve cosmetic appearance and functionality. Like many part inconsistencies, these unwanted features are rooted in product design. Web three terms that often. Web knit lines are a common defect in injection molding that can affect the appearance and performance of plastic parts. Wavy lines are another feature of weld lines. This line typically emerges when these fronts are unable to seamlessly merge or “weld” together. These can occur due to various factors such as the design of the mold, material properties, or processing conditions. Read on for tips on how to minimize or eliminate knit lines when designing your mold. Meld and knit lines are actually both different types of weld lines. Depending on the resin, resin temperature, mold temperature, and filling speed, knit lines can vary. The fluidity of the plastic plays an important role in the injection molding process, so seeking the help of an expert manufacturer and mold maker is essential. Weld lines usually come in two types: They occur when melt flow fronts collide in a mold cavity. Web avoid knit lines when designing a molded part to improve cosmetic appearance and functionality. Meld lines and knit lines. Let’s review what causes meld and knit line imperfections, how they affect part durability, and what the difference between them is. When two streams of melt meet, they form a weld line, which appears as a linear mark on the surface of the molded part. What are knit lines, and how can you avoid them? These defects are not visible, like small cracks in plastics.

Weld Line (Knit Lines) in Injection Molding │20220816T072815.230Z│Blog

What are Injection Molding Defects and How to Control Them? SMLease

Knit Line Archives Midstate Mold & Engineering

Molding Defects Weld Lines

What is a Knit Line in Injection Molding?

![]()

Injection Molding Weld Line Plastopia

Injection Mold Flaws & How to Prevent Them Flow Lines, Knit Lines, & Blush

What is a Knit Line in Injection Molding?

What Are Knit Lines in Injection Molding, and How Do You Prevent Them

What Are Knit Lines In Injection Molding? Rex Plastics

Weld Lines May Appear Like Seams Or Scratches, But That Is Not What They Are.

Present No Problem At All, Be A Cosmetic Issue, Or Cause A.

What Causes Knit And Meld Lines?

Like Many Part Inconsistencies, These Unwanted Features Are Rooted In Product Design.

Related Post: